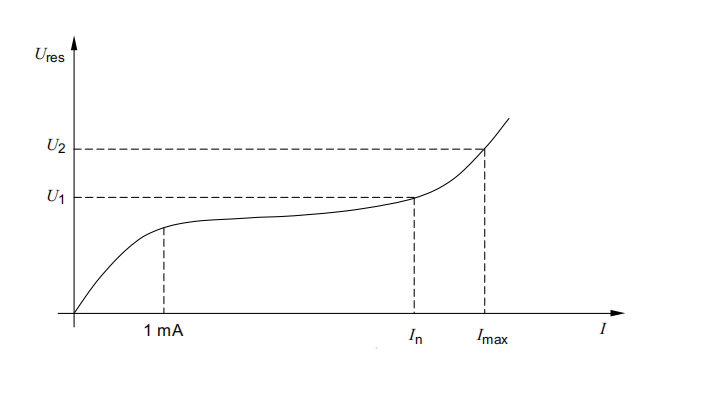

①High energy MOV technology

Voltage limiting type SPD per IEC 61643

High energy AC/DC MOV is employed for PROSURGE’s class I, Class II and Class III AC/DC/PV SPD with compact size.

Advantage of MOV (Metal oxide varistor)

*Higher lightning & surge current discharge capacity

*Wide voltage range to cover AC/DC/PV application

*Fast response

*Wide working temperature

*No follow current in case of surge events

*End of life through thermal runaway, make thermal protection possible

*Stable performance in a long period time.

*Compact size

*Not influenced by various environmental factors while well encapsulated, especially suitable for application in higher altitude,offshore(e.g. offshore windfarms), dust, hot and moisture circumstances

The heat generated by a MOV in end-of-life conditions can be sufficient to cause dangerous overheating of the SPD and even cause the SPD to catch fire.

To keep the SPD and system protected safe, thermal protection is used in all PROSURGE’s MOV type SPD

②PROSURGE patented thermal protection technology

√ Fast response to abnormal heat of MOV body

√ Surge withstand coordination with the SPD surge rating

√ Fast disconnect and cutoff the circuit in case of SPD failure

③PROSURGE patented arc-extinguish technology

Because of an arc between contact may happen while thermal disconnector open, even the arc current lasts for a short time, that will lead to MOV short-circuit failure.

PROSURGE patented arc-extinguish device will ensure permanently and securely disconnected from the power system, and cutoff AC arc /short circuit to prevent fire hazard

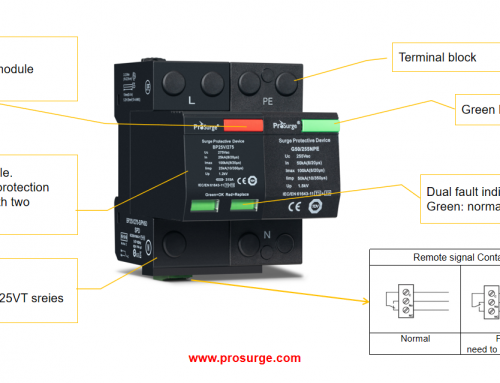

④PROSURGE VT technology

Combination type SPD per IEC 61643

To enhance TOV performance of SPD, Prosurge develop VT technology. The SPD with VT technology will be more robust for the grid voltage fluctuation.

Advantage of PROSURGE VT technology

√ Higher lightning & surge current discharge capacity

√ Wide voltage range to cover AC/DC/PV application

√ Higher TOV withstanding performance without any degradation to the level of protection.

√ No leakage current and follow current in case of surge events.

√ No aging in normal working state.

√ Thermal protection and safe disconnection in end-of-life.

√ Not influenced by various environmental factors while well encapsulated, especially suitable for application in higher altitude,offshore(e.g. offshore windfarms), dust, hot and moisture circumstances

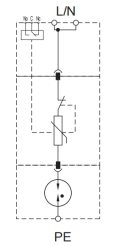

⑤High energy Gas Discharge Tube (GDT) technology

voltage switching type SPD per IEC 61643

High energy GDT was used in N-PE module as ”3+1”protection circuit, It’s important to TT system, the SPDs with “3+1” protection circuit can be installed upstream of the RCD to protect it and prevent unwanted tripping by surge current.(please refer P50 )

The GDT has the following advantages to meet requirements while used in “3+1” protection circuit.

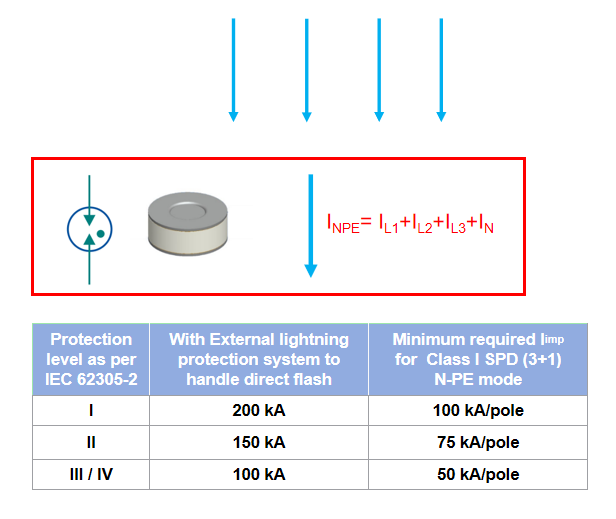

√ Very high lightning discharge current rating. To Class I /T1 SPD, must meet special requirements since in this case the sum of the partial discharge currents from L1, L2, L3 and N must be conducted.

e.g. to Protection level I, T1 SPDs between N and PE must have a lightning current carrying capability of at least Iimp ≥ 100 kA (10/350μs) for three phase systems.

√ must be capable of extinguishing follow currents of 100 Arms due to a possible shifting of the neutral point.

√ A N-PE SPD must fulfil increased TOV requirement. According to IEC 60364-5-53 (HD 60364-5-534), a withstand capability of 1200 V for 200ms must be proven.