The grounding of lightning protection devices to prevent lightning overvoltage is usually referred to as lightning protection grounding. Lightning protection devices must have good grounding in order to effectively limit atmospheric overvoltage and scattered lightning currents. Below, the editor will popularize lightning protection and grounding knowledge for you, hoping to be helpful to you!

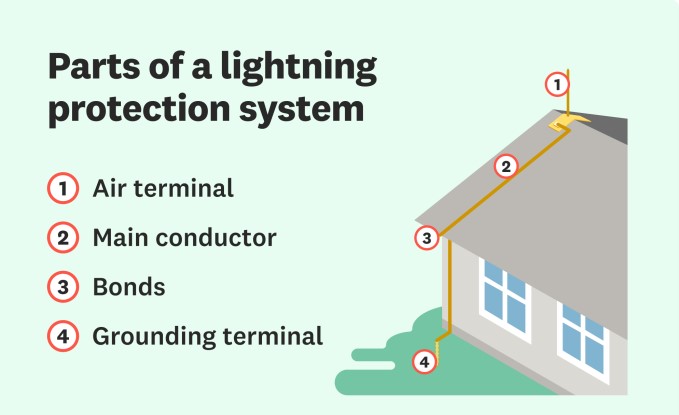

Lightning protection grounding map:

The lightning protection device consists of three parts: the lightning arrester (also known as the lightning receiving device. It is a metal rod that directly or indirectly receives lightning, such as lightning rods, lightning strips or lightning nets, as well as overhead ground wires), the down conductor (also known as the grounding wire. It is a metal conductor used to connect the lightning arrester to the grounding device), and the grounding device. The materials used for lightning protection devices should have sufficient mechanical strength and also meet the requirements of corrosion resistance.

In general, the material specifications selected according to these two principles can meet the requirements of dynamic stability and thermal stability when passing through lightning current. The so-called dynamic stability refers to the ability to resist the mechanical damage caused by lightning currents; The so-called thermal stability refers to the ability to resist the thermal damage caused by lightning currents.

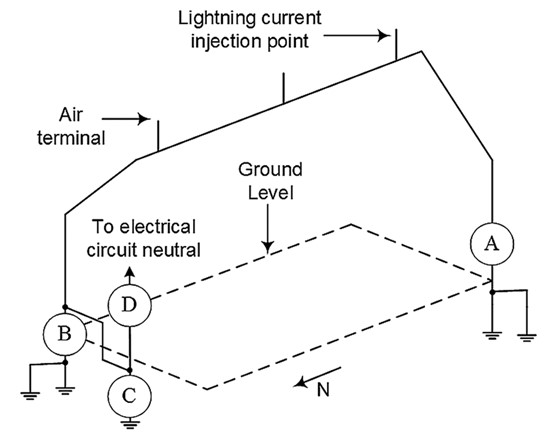

Lightning protection grounding is a grounding method that quickly introduces lightning current into the ground to prevent lightning damage. The type and structure of its grounding device are no different from the working or safety grounding of general electrical equipment. The difference is that lightning protection grounding is conducted to discharge lightning into the ground, while working or safety grounding is conducted to discharge power frequency short-circuit current into the ground.

The power frequency short-circuit current is much smaller than the lightning current, and the voltage drop generated when passing through the grounding device is not significant, so there will be no rebound phenomenon. When lightning current flows through the grounding device, the voltage drop is often much higher, which can cause backlash against certain insulation weaknesses or gaps (when lightning waves flow along the independent lightning rod grounding lead and grounding body to the ground, high voltage will be generated due to the inductance of the lead and the grounding resistance of the grounding body. If the protected object is not sufficiently far away from its grounding device in the air, this high voltage will cause backlash discharge on the protected object).

Due to the severe rebound phenomenon of lightning rods and lightning wires, independent grounding devices need to be installed for them. The conduction and leakage current of lightning arresters and discharge gaps are generally within the lightning resistance level of electrical insulation, and are unlikely to cause counterattacks. Therefore, they can be used in conjunction with general electrical equipment or safety grounding devices without the need for separate installation. In addition, when overhead power lines are directly struck by lightning or lightning strikes occur near the lines, induced overvoltages of up to several hundred kilovolts will be formed on the lines and transmitted into buildings along the two ends of the lines. This phenomenon is called high potential introduction. To prevent high potential from causing injury, a grounding device is also required.